Malaysian customers achieve new breakthrough in environmental emissions: our ion exchange resin helps partner companies meet production standards

Ion exchange resins customer background

A large mining company in Malaysia has long been committed to environmentally friendly production. Its wastewater treatment process has strict requirements on the performance and compliance of ion exchange resins . Under the increasingly tightened environmental protection policies, the company urgently needs to upgrade its existing solutions to achieve sustainable operations.

Core Challenges

Local emission standards are required to be below 1ppm, but the original supplier's resin products cannot meet the requirements

Frequent replacement of resins leads to rising operating costs and faces the risk of environmental penalties

Lack of customized technical support makes it difficult to match the special needs of the production line

Solutions

After in-depth research on the customer's production line conditions, East Chemical specifically recommends high-performance ion exchange resin products

✔️ Precise adaptation: Customize resin models according to water quality characteristics to ensure maximum ion exchange efficiency

✔️ Compliance guarantee: Pass third-party testing and certification, fully comply with Malaysian environmental protection standards

✔️ Long-term stability: Anti-pollution design extends service life and reduces comprehensive operation and maintenance costs by 30%+

Cooperation results

After replacing our ion exchange resin, it is effectively controlled below 1ppm to avoid potential risks.

Deep mutual trust and common development

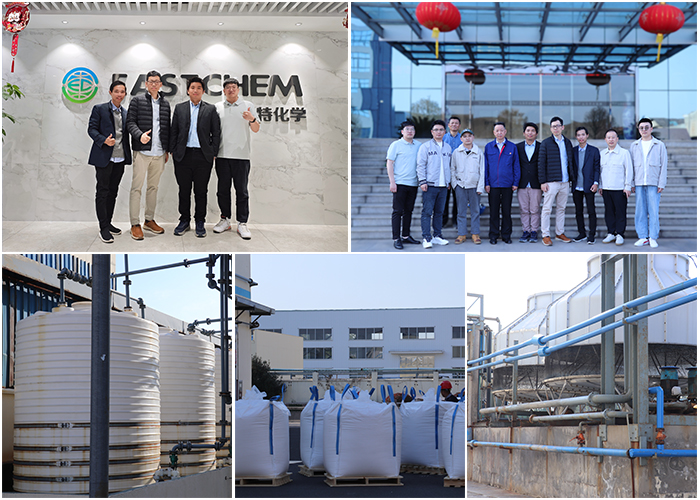

The customer's senior management and technical team visited our headquarters in March to complete the full-link factory audit:

✅ On-site inspection of the intelligent production line and ISO quality control system

✅ Technical exchange meeting to share the industry's cutting-edge resin application solutions

✅ Visit the R&D center and experience the rapid response testing service