Dimethyl Sulfoxide (DMSO) in API and Pharmaceutical Intermediate Manufacturing:

In the pharmaceutical industry, solvent selection plays a critical role in determining product quality, process efficiency, and regulatory compliance. Among high-performance polar aprotic solvents, dmso has gained long-term recognition for its unique physicochemical properties and broad applicability in active pharmaceutical ingredient (API) and pharmaceutical intermediate manufacturing. Chemically known as dimethyl sulfoxide or (Methylsulfinyl)methane, this solvent has become an indispensable material in modern pharmaceutical synthesis.

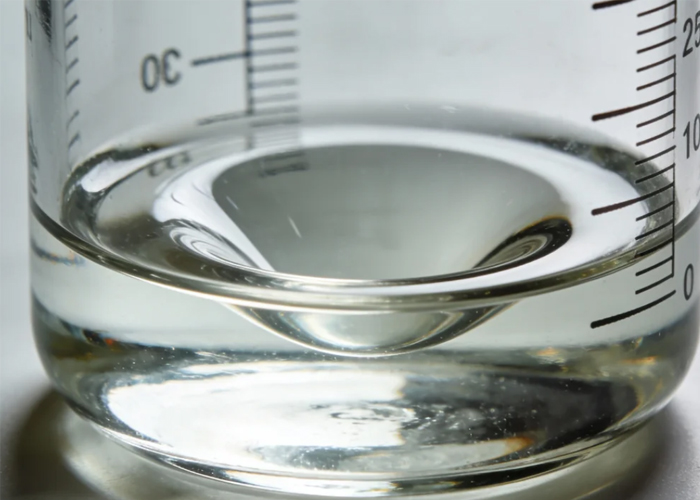

Dimethyl sulfoxide is a colorless, odorless liquid with exceptional solvency. Its ability to dissolve both polar and nonpolar compounds allows dmso to be widely used in complex reaction systems, especially where conventional solvents fail to provide sufficient solubility. In API production, this property helps improve reaction homogeneity, increase yield, and enhance reaction controllability, which is particularly valuable for high-value pharmaceutical intermediates.

From a chemical structure perspective, (Methylsulfinyl)methane contains a highly polar sulfoxide group, enabling strong interactions with a wide range of organic and inorganic compounds. This makes dmso suitable for nucleophilic substitution, oxidation, and condensation reactions frequently encountered in pharmaceutical synthesis routes. As a result, dimethyl sulfoxide is often selected during process development and scale-up stages.

In pharmaceutical intermediate manufacturing, dmso is commonly used as a reaction solvent, crystallization medium, and process aid. Its high boiling point allows reactions to be conducted at elevated temperatures without excessive solvent loss, while its thermal stability ensures consistent performance throughout multi-step synthesis. Compared with other polar solvents, dimethyl sulfoxide offers a favorable balance between solvency strength and chemical stability.

Regulatory acceptance is another important reason for the widespread use of (Methylsulfinyl)methane in pharmaceutical applications. High-purity pharmaceutical-grade dmso can meet stringent quality standards when properly controlled during production and purification. This makes dimethyl sulfoxide suitable for use in regulated API processes, provided that residual solvent levels are managed in accordance with pharmacopeial guidelines.

In addition, dmso is valued for its compatibility with a wide range of active molecules. Many pharmaceutical companies rely on dimethyl sulfoxide during early-stage research, pilot production, and commercial manufacturing of intermediates. Its consistent performance helps reduce process variability and supports reproducible product quality.

From an industry perspective, the demand for (Methylsulfinyl)methane continues to grow alongside the expansion of global pharmaceutical manufacturing. As more complex molecules enter development pipelines, the need for reliable, high-performance solvents such as dmso becomes increasingly evident. For pharmaceutical producers, selecting a stable and high-quality dimethyl sulfoxide supplier is essential to ensure long-term process reliability.

In conclusion, dmso, also known as dimethyl sulfoxide or (Methylsulfinyl)methane, remains a key solvent in API and pharmaceutical intermediate production. Its excellent solvency, thermal stability, and regulatory adaptability make it a preferred choice across diverse pharmaceutical applications. As the pharmaceutical industry continues to advance toward higher complexity and stricter quality requirements, dimethyl sulfoxide is expected to maintain its strategic importance in pharmaceutical synthesis.