Polycarboxylate Superplasticizer

- EASTCHEM

- China

- 15~20 days

Our water reducers not only make concrete use less water and flow better, but also achieve strength quickly, making your construction more efficient and stable while reducing material waste.

Products Description

Our PCE powder is a new type of high-performance polycarboxylate water-reducing agent designed specifically for cement- and gypsum-based mortars. It not only exhibits excellent fluidity and a high water-reducing rate, but also rapidly plasticizes the mortar, maintaining high strength and construction stability. This significantly improves construction efficiency and reduces material loss. Whether your mortar formulation requires high fluidity or high strength, our product offers a stable and adaptable solution, ensuring the quality of your project.

Prouducts Specification

Test Items | Standard | Test Result | |

Water reduction rate % not less than (≥) | 25 | 39 | |

Ratio of bleeding rate at normal pressure% Not more than (≤) | 60 | 35 | |

Air content % not more than (≤) | 6.0 | 3.5 | |

Setting time difference of concrete (mim) | Initial | -90~+120 | +20 |

Finial | +40 | ||

Ratio of compressive strength % not less than (≥) | 1d | 170 | 185 |

3d | 160 | 170 | |

7d | 150 | 165 | |

28d | 140 | 154 | |

Shrinkage ratio % not less than (≤) | 28d | 110 | 75 |

Corrosion to rebar | Yes or No | No | |

Product Advantages

Significant Water Savings and Improved Construction Efficiency

Our polycarboxylate superplasticizer offers a high water-reducing rate and excellent dispersibility. Its saturated dosage can exceed 40%, effectively reducing water usage and improving concrete fluidity, helping you save costs and increase efficiency during construction.

Accelerates Early Strength Development and Ensures Project Quality

This product exhibits excellent early strength enhancement, significantly increasing early strength, improving concrete shrinkage, and reducing carbonation, making your project more stable and durable.

Comprehensively Improves Concrete Durability

It significantly enhances the initial and final strength of concrete, improves its waterproofing and frost resistance, and offers strong resistance to alkali-aggregate reactivity, ensuring long-term performance and safeguarding project quality.

Compatible with a Wide Range of Cement and Admixtures

It has excellent dispersibility in ordinary Portland cement, slag Portland cement, and various admixtures, offering great construction flexibility and stable compatibility regardless of project requirements.

Excellent slump retention

Effectively extends concrete transportation time and on-site residence time, ensuring pumping performance and reducing construction risks and rework costs.

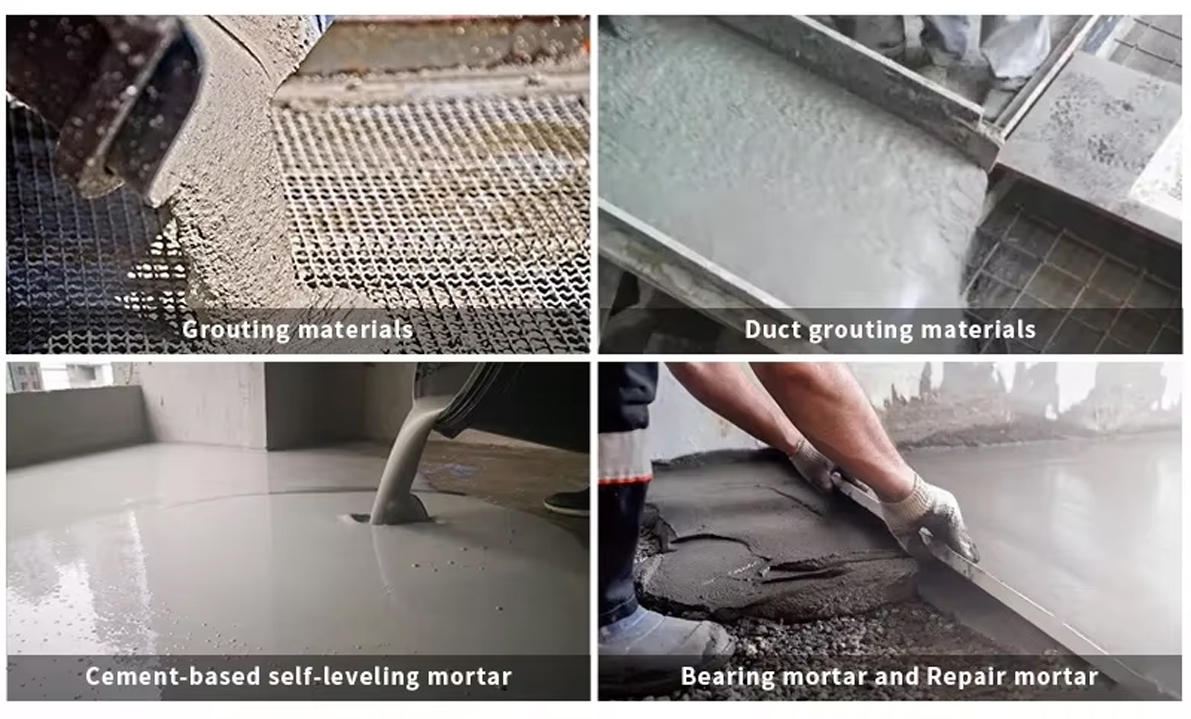

Product Applications

Our polycarboxylate superplasticizers can be widely used in various mortars and cementitious materials, ensuring fluidity and pumpability during construction while also enhancing final strength and durability. Typical applications include:

Grouts: Rapid plasticization ensures structural stability and high construction efficiency.

Pipeline grouting: Excellent fluidity, uniform filling, and reduced construction risks.

Cementitious self-leveling mortar: High flow, high strength, and excellent surface smoothness, reducing rework.

Load-bearing mortars and repair mortars: Significant early strength, high durability, and stable long-term performance.

Recommended Dosage and Usage

Recommended Dosage: 0.3%-0.6% of the total cementitious material. The specific dosage can be determined through pilot testing.

Usage: Mix with sand, stone, cement, and admixtures simultaneously or later with the mixing water. Stir for at least 120 seconds to ensure uniform dispersion and water reduction.

Precautions

Avoid direct mixing with naphthalene-based water reducers or other compounding products.

Be sure to conduct a pilot test before mixing with other admixtures.

Storage and Shelf Life

Store in a cool, dry place, away from direct sunlight.

Shelf life: 12 months. Retest to confirm performance after the expiration date.