polymethylene polyphenyl isocyanate(PM 200)

- EASTCHEM

- China

- 15~20 days

It is, therefore, particularly suitable for the production which require strict flowability of systems.

Product introduction

polymethylene polyphenyl isocyanate(PM 200) is a diisocyanate-diphenylmethane(MDI)-based composition containing some higher functionality isocyanates. The functionality is about 2.6-2.7. It is a brown liquid at ambient temperatures.

Product specification

| Test Item(s) | Specification(s) |

| Appearance | Brown Liquid |

| Viscosity(25°C)/(mPa·s) | 150-250 |

| NCO Content/% | 30.5-32.0 |

| Density (25°C)/(g/cm3) | 1.220-1.250 |

| Acid Content/% | ≤0.030 |

| Hydrolysable Chlorine/% | ≤0.20 |

Product application

Polymethylene polyphenyl isocyanate PM 200 is a material with great application potential and is widely used in the production of rigid polyurethane foam insulation materials. This type of material is of great significance in the construction industry, as it can effectively insulate heat, improve the energy efficiency of buildings and reduce energy consumption. In addition, PM 200 is also suitable for the manufacture of isocyanurate foams, which not only have excellent thermal insulation properties, but are also favored for their heat resistance and chemical stability.

In addition to its application in the foam industry, Polymeric MDI (PMDI) is also suitable for the production of coatings and adhesives. In coatings, Polymeric MDI (PMDI)can improve fluidity and coverage, providing a more uniform coating effect. In adhesives, its addition can enhance bonding strength and improve product durability and performance.

In the application of structural foams and honeycomb self-skin foams, PM 200 can provide good mechanical strength and toughness, suitable for use in demanding industrial products. The automotive industry also benefits from the properties of PM 200, especially in the manufacture of bumpers and interior parts, which can achieve lightweight design while providing good collision protection and comfort.

Polymethylene polyphenyl isocyanate PM 200 demonstrates its diverse performance advantages in the application of high-resilience foam and synthetic wood. High-resilience foam is commonly used in products such as furniture and mattresses to provide good support and comfort. In the production of synthetic wood, PM 200 helps achieve better processing performance and durability.

With its wide range of applications and excellent performance, polymethylene polyphenyl isocyanate Polymethylene polyphenyl isocyanate PM 200 has become an indispensable key material in many industries, meeting the needs of modern manufacturing and design for high-performance materials.

Product advantages

PM 200 can effectively reduce viscosity, ensure that the material can flow quickly and evenly during processing, and reduce the generation of bubbles and defects.

PM 200 performs particularly well in production situations where strict requirements are placed on the fluidity of the system. For example, when manufacturing foam parts with complex shapes, excellent fluidity can ensure that the material fully fills every detail of the mold to form a high-quality finished product. In addition, in efficient production and large-scale manufacturing, fluidity directly affects production efficiency. The excellent performance of PM 200 can shorten production cycles and increase output.

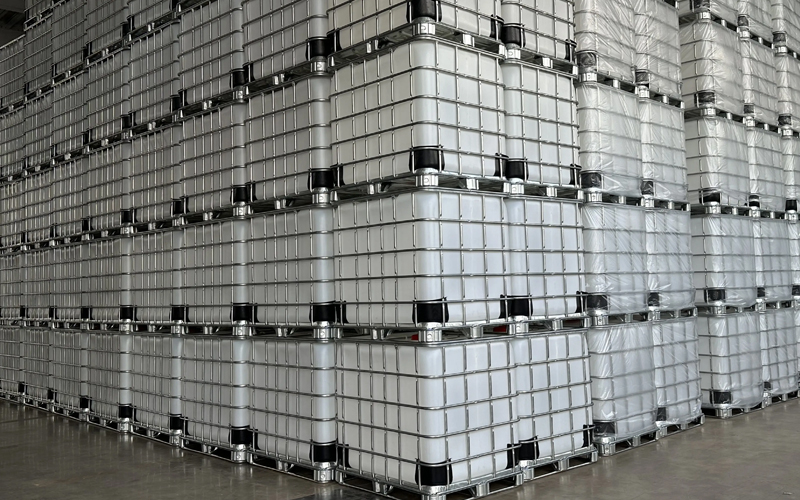

Packaging & Storage

PM 200 is packaged in 210L iron barrels, each weighing 250kg, to ensure the integrity and safety of the material during transportation and storage.

Storage precautions

Since PM 200 is an active chemical substance, it easily reacts with moisture in the atmosphere to generate insoluble urea and carbon dioxide gas, which may lead to increased pressure in the closed container and increased product viscosity. Therefore, the container must be kept absolutely dry and carefully sealed after being filled with nitrogen.

To ensure the quality of PM 200, it is recommended to store it in a well-ventilated place at indoor ambient temperature (15-35℃). Low temperature environment below 5℃ may cause crystallization of the material, so frost on the material should be avoided.

If crystallization occurs, heat the material in a hot air furnace at 70-80℃ and gently roll the barrel to promote its melting. Be sure to stir it thoroughly before use. Never use a water bath for heating, and it is not recommended to store it for a long time at a temperature above 50℃ to prevent the formation of insoluble solids and increase in viscosity.

Following the above packaging and storage guidelines will help maintain the performance and stability of the PM 200 and ensure its efficient performance during use.

Service Guarantee

1. Customized services (providing personalized care with 100% user satisfaction throughout the process, meeting special needs of users beyond standardized services) 2. Productized services (providing professional product solutions based on customer usage scenarios) 3. Proactive services (regular return visit system, regular questionnaires, open and transparent complaint mechanism) 4. Standardized services (based on the technical service standards of the ISO9001 quality management system, forming standardized operating procedures, standardized traceability systems, etc.) 5. Effectiveness of services (8-hour rapid response; 24-hour on-site arrival to ensure timely resolution of problems)